In heavy industrial sectors, reducers are important for regulating the operation of machines and equipment with large torque and low speed requirements. In these sectors, reducers are used to increase productivity, optimize energy efficiency and prevent overload. Some examples of reducer use in heavy industrial sectors are:

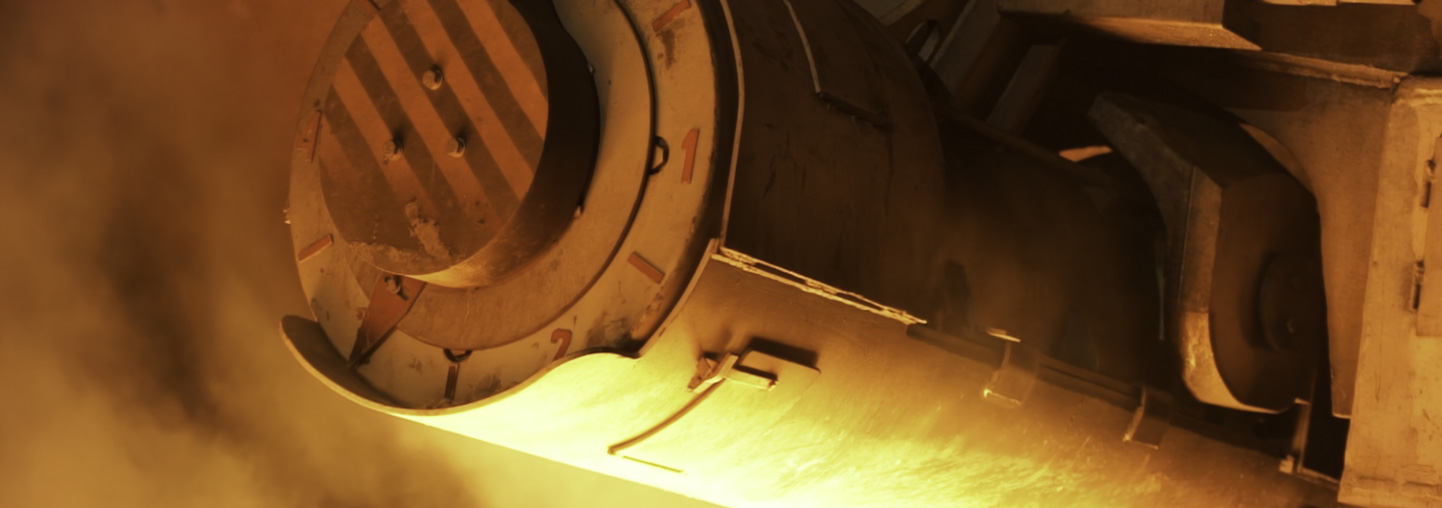

Steel Production: Steel production is a key component of heavy industry. In this sector, reducers are used in rolling mills, foundries and annealing furnaces. Reducers control the rotational movement of rolling mills, casting machines and furnaces.

Mining and Mineral Processing: Large machines used in mining facilities require large torque to extract and process minerals. Reducers are used in many mining equipment, from excavators to conveyor systems and crusher machines.

Power Generation: In heavy industrial power generation facilities, gearboxes are often used in turbines, generators and other power generation equipment.

Maritime and Port Operations: Large cargo ships, port equipment and cranes have reducers. Reducers control the load carrying and processing capacity of these equipment

Rail Transportation: In the railway industry, reducers of locomotives and trains enable them to move safely and efficiently on the rails.

Heavy Transportation and Construction: Large transportation vehicles and construction machinery are equipped with reducers to transport and process heavy loads.

Cement and Concrete Production: Cement plants and concrete plants contain large mills, mixers and conveyor systems powered by reducers.

Waste Management and Recycling: Waste facilities use reducers to process and recycle waste.

These examples demonstrate the wide range of applications of gear units in heavy industrial sectors. Reducers ensure efficient and safe operation of machines in these sectors, prevent overloading and wear, and save energy. Therefore, in heavy industrial sectors, reducers help businesses increase their productivity and profitability.